Solutions

Boiler optimization

-

Improving the performance and longevity of your boiler

-

-

The energy optimization of centralized equipment proposed by Index+ makes it possible, for an existing or new building, to master and monitor the energy consumption connected to heating, air conditioning and ventilation.

It is meant primarily for the kind of centralized equipment that can be found in schools, apartment buildings, public buildings, day care centers, shopping centers and other kinds of non-industrial buildings.

At the current time, we realize that a lot of existing equipment does not function in an optimal manner and that there is an enormous excess consumption of energy that residents are not aware of. The product supplied by Index+ thus puts in place a simple system making it possible to highlight problematic consumption and to reduce operating costs.

Introduction of the product

The product sold by Index+ called “Boiler optimization” includes both material and services that make it possible to:

- Have a concrete understanding of the building’s consumption

- Analyze the existing situation

- Increase the output of the equipment

- Have an accurate view of who is consuming what

- Reduce consumption and operating costs

-

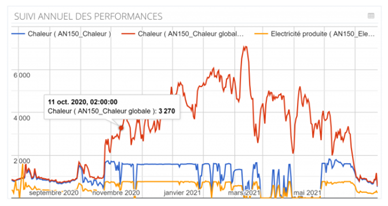

Monitoring

The first points make it possible to provide users with the data of their equipment on an online platform accessible to all members of the team This part provides both the readings from energy meters as well as visuals that allow the user to make their own analyses.

-

Analysis

This part allows the Index+ team to carry out an audit of the boiler by analyzing it visually on site and by analyzing consumption data. This part of the job is divided into two phases.

Phase 1: Analysis of the potential for optimization

The first phase of the project consists in analyzing the equipment, collecting useful information and analyzing if substantial savings can be made and if an optimization phase makes financial sense for the client.

It includes an installation visit, the implementation of a scanner to collect ignition, temperature and time data.

The scanner is installed by Index+ for a period of two months in a way that is simple and non-intrusive.

Next, Index+ collects the supplier invoices and analyses the annual consumption. Then we establish an analytical report with the information collected and of the potential for optimization.

(As an optional extra, we can perform an audit in the sense understood by Belgian Energy Performance of Buildings regulations pertaining to boilers)

-

Phase 2: Optimization of the boiler

If phase 1 showed that there was sufficient potential for savings in the building, Index+ will analyze the equipment in detail and will draw up a list of actions to take.

Savings linked to the optimization naturally depend on each piece of equipment and the way in which the equipment is properly adjusted or not.Monitoring

This last step consists in implementing the actions recommended by Index+. This work will be carried out in collaboration with the heating engineers in charge of the equipment, or with Index+’s partners should that be necessary.